Stud welding ARC

Arc stud welding is a widely used process in many industrial applications due to the quality of the weld and its resistance to various technical constraints. The application of this welding method is simple. However, it requires specific qualifications for the welders to ensure their safety and to make durable welds within the specifications of the materials to be welded.

How does stud welding by fusion forging work?

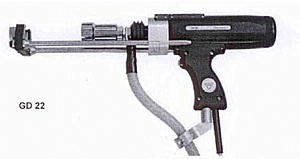

The principle of arc welding is simple. An electric current heats up the metal to its melting point. The technology used by C2G Soudage Innovation guarantees a particularly safe welding process for anchor bolts. Arc welding with a ceramic ferrule generates an electric arc that is ignited between the welding stud and the stud to be welded. This results in a complete fusion between the two.The refractory ceramic ring or ferrule forms a collar that protects the molten pool caused by the voltaic arc from oxidation. They slow down the cooling process to prevent the metal part from losing its characteristics. It is simply removed after the installation. The use of an inert shielding gas can be useful for welding certain air-reactive materials.

What applications use the arc welding process?

The industrial applications using the ARC stud welding process are vast. This technique meets high requirements and constraints, as well as construction and safety standards for the construction of helicopter runways on aircraft carriers in the aeronautics industry, for example.In the field of smoke production, the ARC welding process offers solutions for concrete refractory anchors on the walls of industrial furnaces. The construction industry and civil engineering also require the use of this process for the construction of hydroelectric dams and bridges made of steel structures.

The ARC stud welding process is also standard in the petrochemical industry, heavy boiler making and the construction of civil engineering equipment.

What materials can be welded with the ARC welding process?

Many materials can be welded using the ARC welding process. It is important to know the properties of the metal parts to be welded (oxidation rate, melting point, number of millimetres, etc.) and the studs to be welded in order to use the appropriate welding method.For example, the ARC stud welding process can be used to weld aluminium, cast iron, steel, stainless steel and certain alloys. Welding machines such as the Jupiter 1800 ARC are perfectly suited for welding all types and brands of studs with diameters from 1 to 20 millimetres in Fusion Forging Arc and diameters from 1 to 8 mm in Short Time Arc.