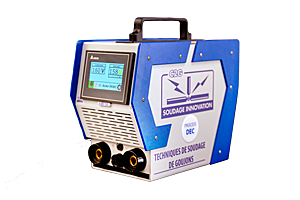

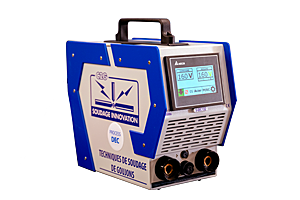

Stud welding DEC

DEC stud welding is a classic stud welding process. It is easy to use. It is very versatile and is reserved for welding on thin sheets of metal because there is no marking on the back of the welded metal part. Many materials can be welded with this process in a wide range of industrial sectors.

How does DEC stud welding work?

To carry out capacitor discharge welding, the stud, equipped with a tip at its end, is placed in contact with the surface of the substrate. The discharge of the capacitor current will pass through the stud to create the melting arc and then the forging of the stud. The stud is then welded to the top of the workpiece.This process is particularly used for the machining of thin sheets where they do not need to be penetrated, deformed or marked on their inner surface (on the reverse side). The welding of studs from 1 to 10 millimetres is of high quality and burr-free thanks to the DEC welding process.

Several welds can be made simultaneously using a special machine. For example, studs with a diameter of 5 and 6 millimetres made of stainless steel can be welded semi-automatically and in impact mode using the capacitor discharge process.

What applications does the DEC welding process have?

Welds made with the DEC process are burr-free. The absence of deformation and marking is a very effective way of keeping the welded metal parts clean during use.This process is therefore recommended in the food industry where the risks of bacterial proliferation and contamination must be kept to a minimum. Indeed, tanks, stainless steel work tables or even kitchen pianos, ovens and refrigerated furniture in the hotel and catering sector are particularly sensitive tools for which it is necessary to comply with the specifications and health standards in force.

The field of fine sheet metal work also uses the capacitor discharge welding (CDW) process for the manufacture of various enclosures and covers in different materials such as steel or stainless steel.