Applications : Fine metal working

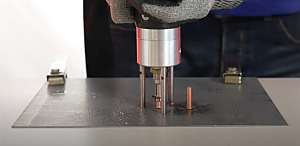

DEC CONTACT WELDING OF COPPER PLATED STEEL STUDS FOR FINE SHEET METAL AND BOILER MAKING APPLICATIONS

The DEC "capacitor discharge" welding process in contact mode is used to weld copper-plated steel studs in a wide range of applications including sheet metal and fine sheet metal work.In contrast to the percussion mode, the stud is in direct contact with the sheet metal to be welded from the start of the welding process.

Another significant advantage of the DEC welding process, compared to the SIG®, ARC or ATC process, is that it leaves no marks on the back of the parts to be joined.

The absence of deformation and marking reduces the post-welding time since the weld is perfect and the fastening point does not need any finishing treatment.

The SDEC 132 welding unit designed by C2G SOUDAGE INNOVATION is the new generation of equipment for welding copper-plated steel studs, which are frequently used in the sheet metal and fine sheet metal industries for the construction of numerous elements such as machine fairings and cable trays, or ground connections in electrical boxes.

In order to provide innovative and practical solutions to operators, C2G proposes to combine the SDEC 132 generator with a gun equipped with a 3-leg system to facilitate the welder's work. This ensures a perfect connection over the entire contact surface.

In addition, the SDEC 132's digital display allows the operator to check in an instant that he is following the instructions and measurements useful for his welding, as well as the process, the material and the diameter of the stud to be welded. This avoids the risk of error and saves time and comfort for the operator.