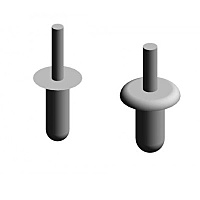

Other fasteners, clinching / WELDING NUT

In the field of welding, weld nuts are materials used in many industries. Their many advantages make them perfectly suited for assemblies in different materials and for different sheet thicknesses. In particular, they are resistant over time and have a good steel quality.

They are very versatile and can be used to weld different metals using different welding processes. The various square and hexagonal shapes and the wide range of diameters allow for a wide variety of assembly possibilities. As with press-fit nuts and studs, weld nuts offer low investment and high productivity.

A wide range of applications

C2G offers a wide range of weld nuts for welding thin sheet metal for fine sheet metal work, thick metals for smoke extraction or for welding specific and professional equipment for the hotel industry.The use of weld nuts is suitable for the food industry as well as for the automotive industry for the fixing of body parts for example. They are also very suitable for assembling the various metal parts that make up train seats and will be resistant for outdoor use in the construction of engineering structures and bridges.

Multiple advantages: versatility, strength, ease of use

The versatility of weld nuts allows them to be used on all types of supports in different materials such as steel or stainless steel. The different models, shapes, sizes and dimensions offer numerous fastening possibilities with a very high resistance. The threaded hole is also very strong when welding thin sheet metal.The high quality of C2G Innovation's nuts makes them suitable for both indoor and outdoor use. Their strength allows for a very high clamping force, ensuring that the assembled parts are perfectly solid.

Another advantage of using a weld nut is that no pre-drilling is required before welding. This allows for increased productivity while maintaining optimum fastening quality. Also, the cost of this type of material is very low.

Welding processes for weld nuts

Nuts can be welded using different welding processes. The use of ARC, DEC, ATC and SIG® welding techniques is possible with a very high fixing quality. It is only necessary to use the right type of nut (inner and outer diameter, pitch, shape, etc.) for the intended assembly of the parts.

Thus, when manufacturing equipment for large professional kitchens, a welding machine specific to the DEC process will allow the welding of nuts that meet the requirements of safety, hygiene and durability.

C2G, your online expert, is at your disposal for any personalized information on welding nuts