Applications : Food processing

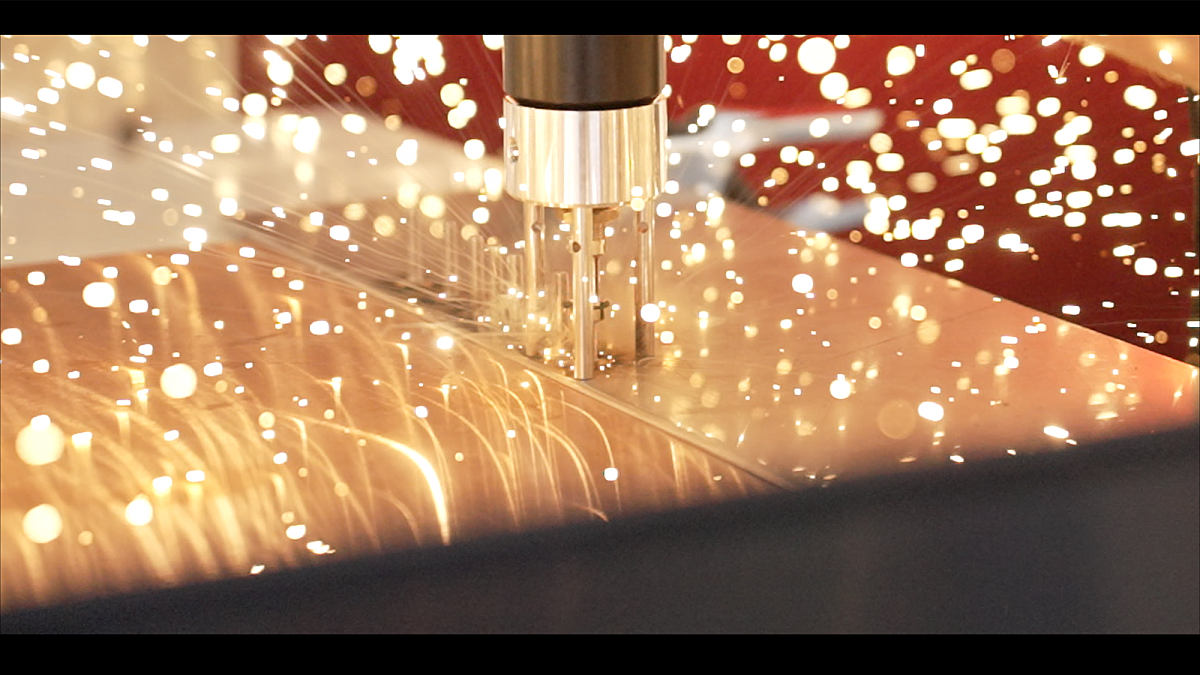

DEC stud welding for stainless steel sheet metal applications

Process : Stud welding DEC

DEC stud welding in percussion mode is perfectly suited for thin sheet metal applications. Indeed, the absence of marking on the back of the stainless steel sheet provides :

- numerous guarantees in terms of hygiene,

- increased solidity of the fastening point which is maintained over time,

- a perfect visual appearance.

The DEC process is therefore ideal for the food industry, and also for the manufacture of large kitchen furniture and hotel equipment (work tables, pianos, refrigerated furniture, ovens, etc.).

For example, the SDEC 132 generator in percussion mode developed by C2G SOUDAGE INNOVATION, a manufacturer of welding studs, is a concentrate of innovations and advanced technologies. It is lighter and therefore more practical for the operator. Its digital display offers ease of use and limits the risk of error. It has a wide range of pre-recorded programmes and the possibility of creating new ones as required. The operator can see in an instant the setpoint, the measurement, which process he is welding, and on which material.

The gun can be equipped with a 3-leg system to ensure a perfect bond over the entire contact area between the stud and the sheet metal. The impact is made by a simple pressure on the gun. The three feet provide perfect stability, so that the operator can work effortlessly. The operator can easily repeat the operation without fatigue.

Many types of anchor bolts can be used with this equipment to fix a variety of products.

In our video, we show PT/CF "threaded capacitor" studs in M6x25 stainless steel, which perfectly illustrates the possibilities of welding stainless steel sheet metal studs for large-scale kitchens, the food industry and the pharmaceutical industry, without microbial spots

STAINLESS 304 L or 316 L stud welding on stainless steel furniture for large kitchens.