Applications : Civil engineering, engineering structures, steel and concrete construction

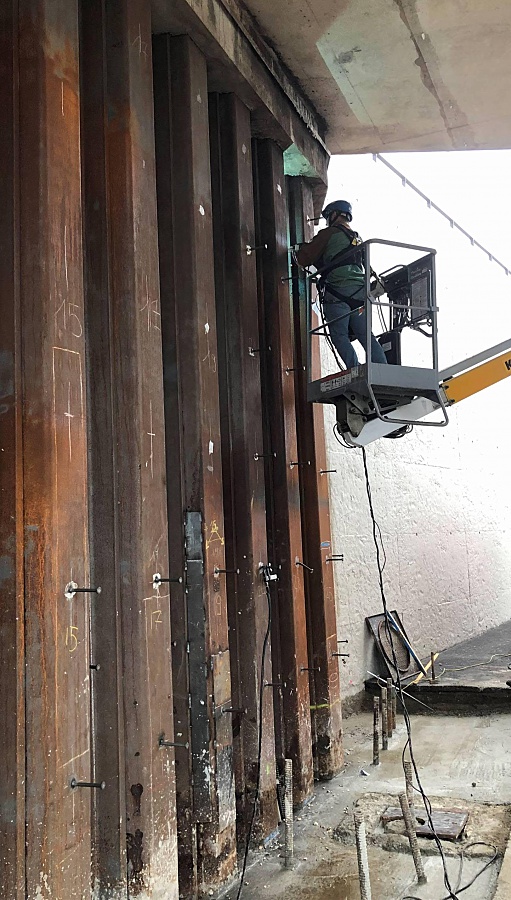

Welding connector studs to the sheet piling under the structure

Process : Stud welding ARC

The AFF "Arc Fusion Forging" stud welding process is commonly used in the construction of steel and composite steel/concrete structures due to its high strength and ease of application. It is therefore particularly suitable for the construction of sheet piling.

The use of a generator adapted to the technical constraints, such as the HERA or JUPITER range of welding machines, and quality anchor bolts offer a very long service life for the constructions and also ensure that the operators work in complete safety.

The reinforcement solution for the use of connector studs in the construction of a sheet pile wall under a structure consists of several phases. In the first step, a reinforced concrete wall is placed against the damaged sheet pile.

This reinforced concrete wall is then connected to the existing headframe and the sheet piling by means of connecting bolts. The role of the connector studs is to transmit the load drop from the sheet piling to the reinforced concrete wall.

Thus, the welding of the SD type connector studs (standard 13918, ABAC 16X150 in S235 steel) can be carried out using the AFF "Arc Fusion Forging" process. The AFF process, although simple to apply, requires the use of a refractory ring in order to protect the fusion bath from oxidation and to obtain a perfect anchoring on the whole connection surface.

WHAT TYPE OF WELDING POSTE IS SUITABLE FOR THE AFF STUD WELDING PROCESS?

Generators using Inverter technology are perfectly suited to stud welding using the AFF (Arc Fusion Forging) process. Indeed, this technology allows a high repeatability and very fast regulation.

Also, in order to increase the safety of the operator, both in the workshop and on site, and whatever the constraints he is confronted with, C2G has created ergonomic, light and easy-to-use welding units such as the HERA and JUPITER range.

For this type of mixed steel/concrete construction of a sheet pile curtain, both power sources meet these criteria. The JUPITER generator will be used in the case where it is not possible to access the power and the use of a 200 KVA generator is required.

The JUPITER 1200 AFF generator, version with transformer, will be used here with a 380/400 three-phase direct box. The HERA 2500 AFF generator will be perfectly suitable if it is possible to draw power from the meter.

The use of a generator adapted to the technical constraints, such as the HERA or JUPITER range of welding machines, and quality anchor bolts offer a very long service life for the constructions and also ensure that the operators work in complete safety.

INSTALLATION OF CONNECTOR STUDS ON A SHEET PILE CURTAIN UNDER A STRUCTURE

The reinforcement solution for the use of connector studs in the construction of a sheet pile wall under a structure consists of several phases. In the first step, a reinforced concrete wall is placed against the damaged sheet pile.

This reinforced concrete wall is then connected to the existing headframe and the sheet piling by means of connecting bolts. The role of the connector studs is to transmit the load drop from the sheet piling to the reinforced concrete wall.

Thus, the welding of the SD type connector studs (standard 13918, ABAC 16X150 in S235 steel) can be carried out using the AFF "Arc Fusion Forging" process. The AFF process, although simple to apply, requires the use of a refractory ring in order to protect the fusion bath from oxidation and to obtain a perfect anchoring on the whole connection surface.

WHAT TYPE OF WELDING POSTE IS SUITABLE FOR THE AFF STUD WELDING PROCESS?

Generators using Inverter technology are perfectly suited to stud welding using the AFF (Arc Fusion Forging) process. Indeed, this technology allows a high repeatability and very fast regulation.

Also, in order to increase the safety of the operator, both in the workshop and on site, and whatever the constraints he is confronted with, C2G has created ergonomic, light and easy-to-use welding units such as the HERA and JUPITER range.

For this type of mixed steel/concrete construction of a sheet pile curtain, both power sources meet these criteria. The JUPITER generator will be used in the case where it is not possible to access the power and the use of a 200 KVA generator is required.

The JUPITER 1200 AFF generator, version with transformer, will be used here with a 380/400 three-phase direct box. The HERA 2500 AFF generator will be perfectly suitable if it is possible to draw power from the meter.