The Eurocode 4 AFNOR programme concerns steel construction, concrete structures, structural steel, and consequently all the rules concerning design, calculations, choice of materials and their resistance to fatigue, stresses and strains, connections and links between beams, slabs of mixed steel-concrete structures, dimensioning rules and types of steel-concrete connectors.

Applications : Civil engineering, engineering structures, steel and concrete construction

WELDABLE CONNECTOR STUDS FOR CONCRETE ANCHORING

Concrete anchors are widely used in the construction industry. The so-called "mixed steel-concrete" construction process is used for many buildings and engineering structures, bridges, car parks, dams and a very wide variety of concrete structures.A mixed structure owes its very important capacities to an ideal structural collaboration between steel and concrete, the respective characteristics of the two materials of very different natures complementing each other in a complementary way, the connection thus ensured being perfect to resist horizontal shear.

Steel is perfect for transmitting tensile forces, while concrete is particularly resistant to compression, protecting the metal from corrosion by offering great thermal inertia and fire resistance.

STANDARDISATION OF SHEAR CONNECTOR STUDS

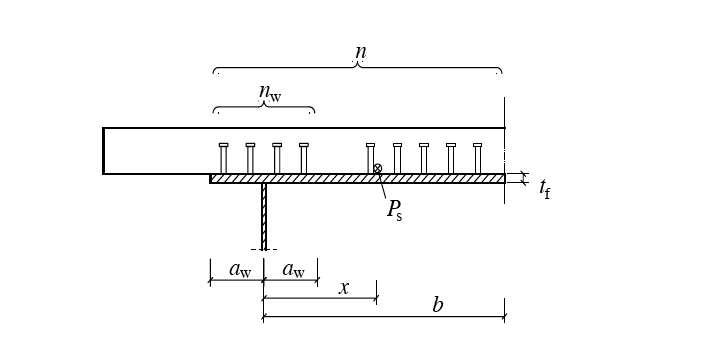

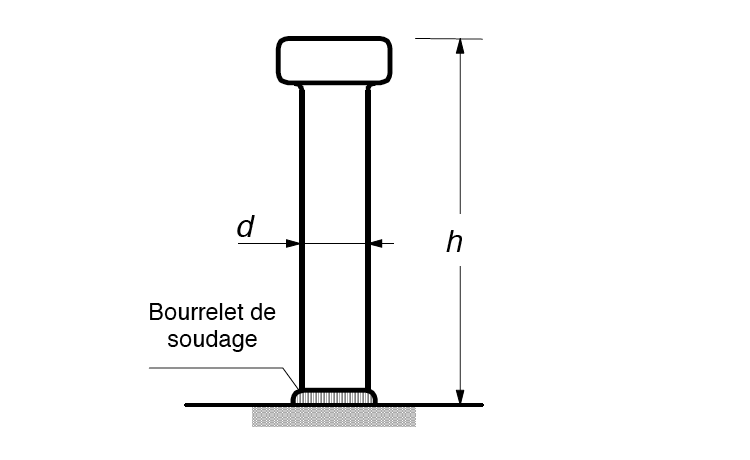

Schémas extraits de la Norme Eurocode 4 AFNOR

Schémas extraits de la Norme Eurocode 4 AFNOR

There are several types of connectors for connecting steel beams and concrete slabs, also referred to as head studs for concrete anchorage application with refractory base are the most commonly used connectors in Europe.

C2G Welding Innovation offers weldable connector studs as standard and also referred to as anchor studs or concrete connectors. The weldable material is a standardised structural steel according to EN ISO 13918, S235J2+C450.

C2G SOUDAGE INNOVATION, FRENCH MANUFACTURER OF WELDING EQUIPMENT AND WELDING STUDS

French stud welding specialist, C2G Soudage Innovation designs and manufactures a range of equipment and machines for stud welding on building sites.The welding process used is Arc Fusion Forging (AFF) with ceramic refractory ring. The company offers various dimensions and diameters from 13 to 31 mm, the 19 mm model being the most commonly used.

HOW DOES STUD WELDING BY ARC FUSION FORGING WORK?

Manufacturer of welding studs and welding generators, C2G guarantees a particularly safe welding process for anchor studs.

Arc welding with a ceramic ferrule generates an electric arc which is initiated between the welding stud and the stud to be welded to which it is to be attached, thus achieving complete fusion between the two.

The refractory ceramic ring or ferrule forms a collar that protects the melt bath caused by the voltaic arc from oxidation and slows down its cooling to avoid a loss of the steel's characteristics, it will simply be removed after installation.

Manufacturer of welding studs and welding generators, C2G Soudage Innovation guarantees a particularly safe welding process for anchor studs.

Arc welding with a ceramic ferrule generates an electric arc which is initiated between the welding stud and the stud to be welded to which it is to be fixed, thus achieving complete fusion between the two.

The refractory ceramic ring or ferrule forms a collar that protects the melt bath caused by the voltaic arc from oxidation and slows down its cooling to avoid a loss of the steel's characteristics, it will simply be removed after installation.

These 2 videos from C2G Welding Innovation show demonstrations of stud fixing and the use of welding generators for concrete anchor fixing.

*Soudage en Arc Fusion Forgeage de goujons connecteur béton

*Soudage de Goujons connecteurs Ancrages de béton AB/SD avec céramique