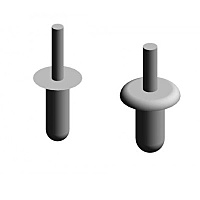

Other fasteners, clinching / THREADED INSERT PLASTIC

Like nuts and studs, threaded inserts for plastics have the same mechanical fastening principles. The combination of different materials in the manufacture of industrial parts must meet the constraints of each in order to obtain an optimal fastening.

They allow the assembly of different types of plastics and installation methods. They are used in many industrial applications such as in the automotive sector, the railway sector or for the manufacture of furniture.

Strong products combined with the flexibility of the plastic material

The flexibility and elasticity of plastic materials, as well as their low weight and cost, are important advantages that invite manufacturers to use them in the manufacture of many products. The technical and mechanical constraints of plastic materials are different from those of metals. In order to obtain a high quality assembly, the threaded inserts are adapted to ensure the performance of your products.The anchorage is strong and reliable during assembly and over time. The thread of the insert is stronger than a screw. They can be installed before, during or after moulding depending on your manufacturing process.

The manufacture of threaded inserts by screw-cutting offers a very high level of robustness and resistance of the thread. The thread is durable over time. The performance of our brass threaded inserts combined with the flexibility of plastic materials provides a fastening solution for the most demanding applications.

Adaptability of threaded inserts for better performance

Brass threaded inserts for plastics are as powerful as they are versatile and adaptable. They can be used for injection moulding, moulding and rotational moulding. The threaded inserts can be inserted into thermoset plastics, thermoplastics as well as harder materials such as resin.Threaded inserts can be welded in several ways. Thermal setting is a joining process in which a fusion between the plastic material and the metal of the insert is formed. The insert can also be welded using electromagnetic resistance or ultrasound.

C2G helps you to design and implement the most suitable solution and to choose the threaded inserts from a wide range according to your needs.

Threaded inserts are used in many fields of application

In the aerospace and railway industries, threaded inserts are commonly used, for example, in the manufacture of seat and door trim parts. Similarly, they are required in the manufacture of upholstery for construction machinery.